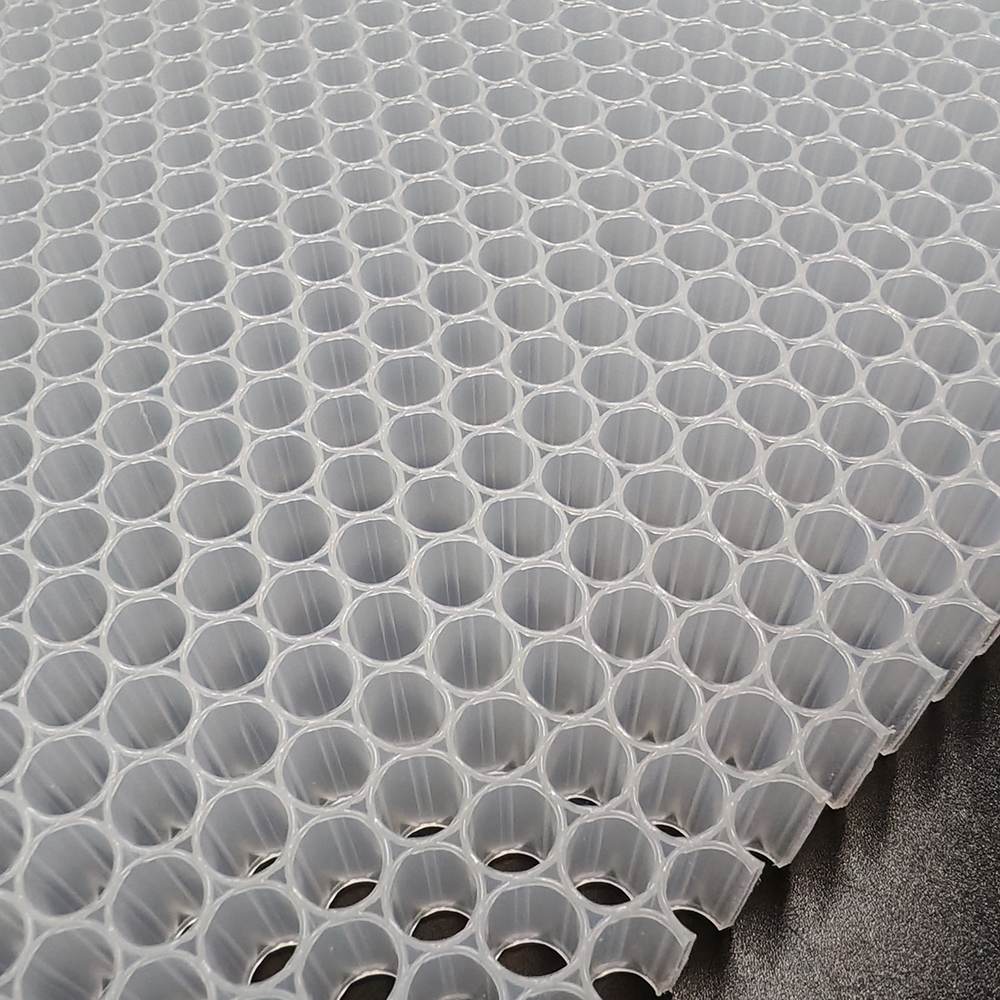

PP Honeycomb Core is a lightweight, high-performance core material manufactured from polypropylene (PP) using an advanced honeycomb structure. It is widely used in composite sandwich panels where high stiffness-to-weight ratio, excellent fatigue resistance, and long-term durability are required. Compared with traditional core materials such as plywood, balsa wood, or solid plastic sheets, PP Honeycomb Core…

PP Honeycomb Core is a lightweight, high-performance core material manufactured from polypropylene (PP) using an advanced honeycomb structure. It is widely used in composite sandwich panels where high stiffness-to-weight ratio, excellent fatigue resistance, and long-term durability are required. Compared with traditional core materials such as plywood, balsa wood, or solid plastic sheets, PP Honeycomb Core delivers superior mechanical efficiency while significantly reducing overall panel weight.

Due to its closed-cell structure, chemical stability, and moisture resistance, PP Honeycomb Core has become an ideal solution for applications in transportation, marine, construction, wind energy, industrial panels, and furniture manufacturing. Its recyclability and long service life also align with modern sustainability and environmental protection requirements.

Material Structure and Manufacturing Technology

PP Honeycomb Core is produced from high-quality polypropylene resin through extrusion and thermoforming processes. The material is formed into a uniform hexagonal honeycomb structure, which provides excellent load distribution and energy absorption properties.

The honeycomb geometry allows forces to be spread evenly across the panel surface, enhancing compressive strength and shear performance while minimizing material usage. The cell size, wall thickness, and density can be precisely controlled during production, enabling customized solutions for different structural and performance requirements.

Unlike paper or aluminum honeycomb cores, PP Honeycomb Core offers a unique combination of flexibility, impact resistance, and resistance to environmental degradation, making it suitable for both indoor and outdoor applications.

Key Performance Advantages

Lightweight with High Structural Efficiency

PP Honeycomb Core provides outstanding stiffness and strength at very low weight. When used as the core in sandwich panels with FRP, aluminum, steel, HPL, or plywood facings, it significantly improves bending stiffness without adding unnecessary mass.

Excellent Moisture and Chemical Resistance

Polypropylene is naturally hydrophobic and resistant to most acids, alkalis, and solvents. PP Honeycomb Core does not absorb water, rot, or swell, making it especially suitable for marine, humid, or chemically aggressive environments.

Superior Fatigue and Impact Resistance

Compared with brittle core materials, PP Honeycomb Core maintains structural integrity under repeated loading and impact. This makes it ideal for transportation floors, container panels, and industrial platforms that experience continuous dynamic stress.

Environmentally Friendly and Recyclable

PP Honeycomb Core is 100% recyclable and free from formaldehyde or harmful emissions. It supports green manufacturing practices and helps end-users meet sustainability goals and regulatory requirements.

Technical Specifications

Below is a typical performance data table for PP Honeycomb Core. Actual values can be adjusted according to density, cell size, and customer requirements.

Physical Properties

| Property | Unit | Typical Value |

|---|---|---|

| Density | kg/m³ | 60 – 120 |

| Cell Size | mm | 6 / 8 / 10 |

| Thickness Range | mm | 5 – 100 |

| Operating Temperature | °C | -40 to +80 |

| Water Absorption | % | < 0.5 |

Mechanical Properties

| Property | Unit | Typical Value |

|---|---|---|

| Compressive Strength | MPa | 0.8 – 2.5 |

| Compressive Modulus | MPa | 30 – 120 |

| Shear Strength | MPa | 0.6 – 1.8 |

| Shear Modulus | MPa | 15 – 80 |

| Peel Strength (with FRP skins) | N/mm | ≥ 1.5 |

Note: Mechanical performance depends on density, bonding method, and facing materials.

Compatibility with Facing Materials

PP Honeycomb Core is compatible with a wide range of skin materials and bonding systems. Surface treatment options such as corona treatment, flame treatment, or non-woven scrim lamination can be applied to improve adhesion performance.

Common facing materials include:

- FRP (Fiberglass Reinforced Plastic)

- Aluminum sheets

- Stainless steel

- Plywood and laminated wood

- HPL and decorative panels

- Thermoplastic sheets

This versatility allows PP Honeycomb Core to be used in both structural and decorative composite panels.

Typical Applications

Transportation Industry

PP Honeycomb Core is extensively used in truck bodies, trailers, RV floors, bus panels, railway interiors, and cargo containers. Its lightweight nature contributes to fuel efficiency and increased payload capacity, while its durability ensures long service life under vibration and repeated loading.

Marine and Offshore

In marine applications, PP Honeycomb Core is used for decks, bulkheads, partitions, and furniture panels. Its resistance to water, salt, and mold makes it a reliable alternative to traditional marine plywood and balsa cores.

Construction and Building Panels

PP Honeycomb Core is applied in wall panels, partition systems, raised floors, and modular building components. It offers consistent performance, dimensional stability, and ease of installation.

Industrial and Furniture Applications

In industrial platforms, clean rooms, and furniture manufacturing, PP Honeycomb Core provides high load-bearing capacity with reduced weight, supporting ergonomic design and easy handling.

Processing and Customization

PP Honeycomb Core can be easily cut, CNC-machined, laminated, and thermoformed. Customized specifications are available to meet specific project requirements, including:

- Customized density and thickness

- Different cell sizes

- Surface treatment for improved bonding

- Pre-laminated composite panels

- Fire-retardant grades (upon request)

This flexibility allows designers and engineers to optimize both performance and cost.

Quality Control and Standards

PP Honeycomb Core is manufactured under strict quality control systems to ensure consistent performance and reliability. Production can comply with international standards and customer-specific testing requirements, including:

- Compression and shear testing

- Fatigue resistance testing

- Environmental aging tests

- Bonding and peel strength evaluation

Each batch can be traced and documented to meet industrial and project certification needs.

Conclusion

PP Honeycomb Core is a modern, high-performance core material that combines lightweight design, mechanical efficiency, durability, and environmental responsibility. Its versatility across multiple industries, combined with excellent processing compatibility and long-term stability, makes it an ideal choice for advanced composite sandwich panels.